Sheet Metal Fabrication in Asia

• 20 Years’ Experience in Sheet Metal Design & Production

• Sheet Metal Production Facilities in China and Thailand.

• Capabilities in Laser Cutting, CNC Bending, Welding, Stamping and more

Our Equipment And Process

Choose Chuckmetal for one-step sheet metal fabrication services. With over 30 sets of advanced machines—including laser cutters, bending machines, and welders—our factory handles everything from low-volume prototypes to high-volume production. Our sheet metal fabricators and a team of knowledgeable engineers ensure that each sheet metal component is manufactured to exact specifications and quality standards.

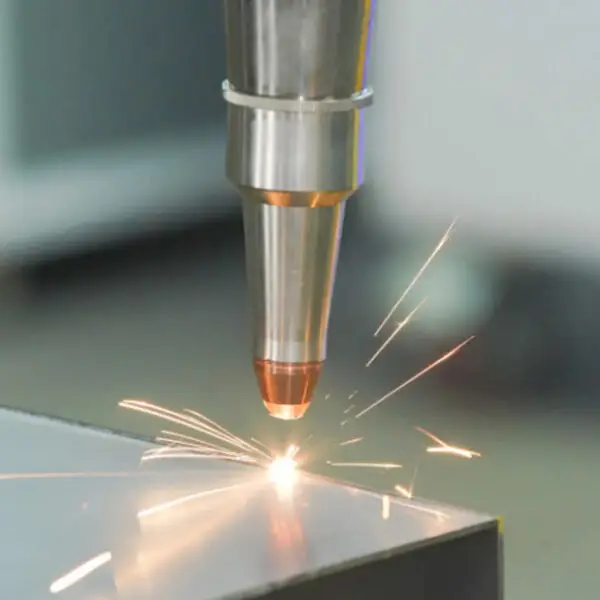

Laser Cutting

Laser cutting uses a focused laser beam to cut, etch, or engrave materials, vaporizing or melting them for precise edges and complex patterns based on designer specifications.

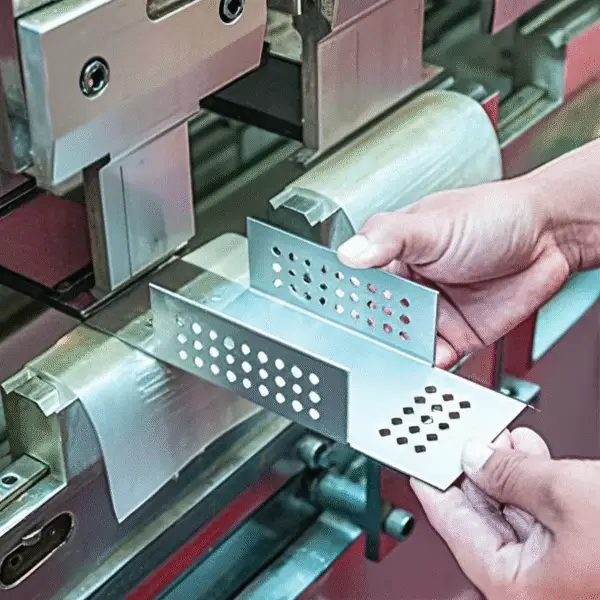

Bending/Folding

Bending applies a force to a thin sheet of metal to shape it into various geometries, like U-shape, V-shape, or channel shape. The thickness of the metal can vary.

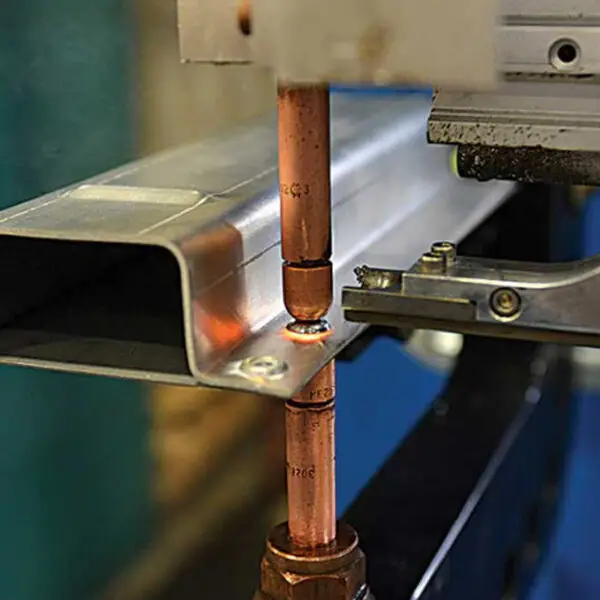

Welding

Welding is the process of joining two or more metal pieces using heat, pressure, or both to form a strong bond. It combines skill and precision to create durable, sturdy metal structures.

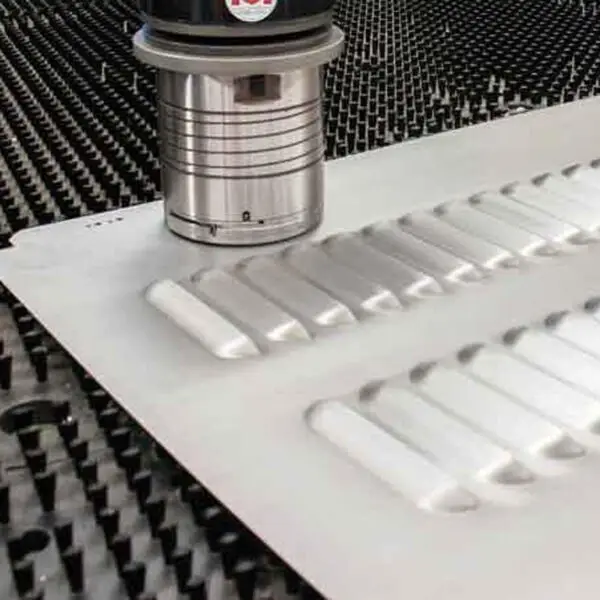

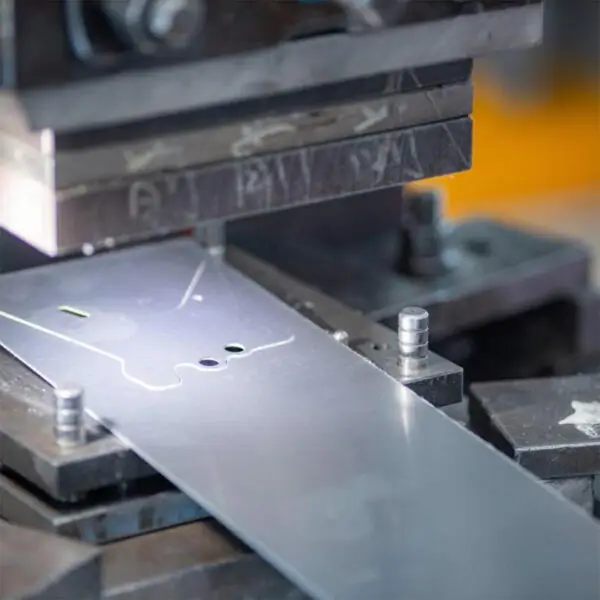

Punching

Punching uses a punch tool to create holes or shapes by forcing it through a die, cutting the metal with a shearing action for precise, clean results in fabrication.

Riveting

Riveting is a semi-permanent joining method using mechanical fasteners (rivets) to connect sheet metal parts. It’s faster and much cost-effective than welding.

Stamping

Stamping uses dies and presses to shape flat metal sheets into different forms, creating complex, three-dimensional designs through cold-forming techniques.

Pressure riveting

Pressure riveting is a non-welding joining process. Riveting components like nuts/screws are embedded into metal sheets under pressure for reliable threaded connections, offering efficiency, aesthetics, and detachability.

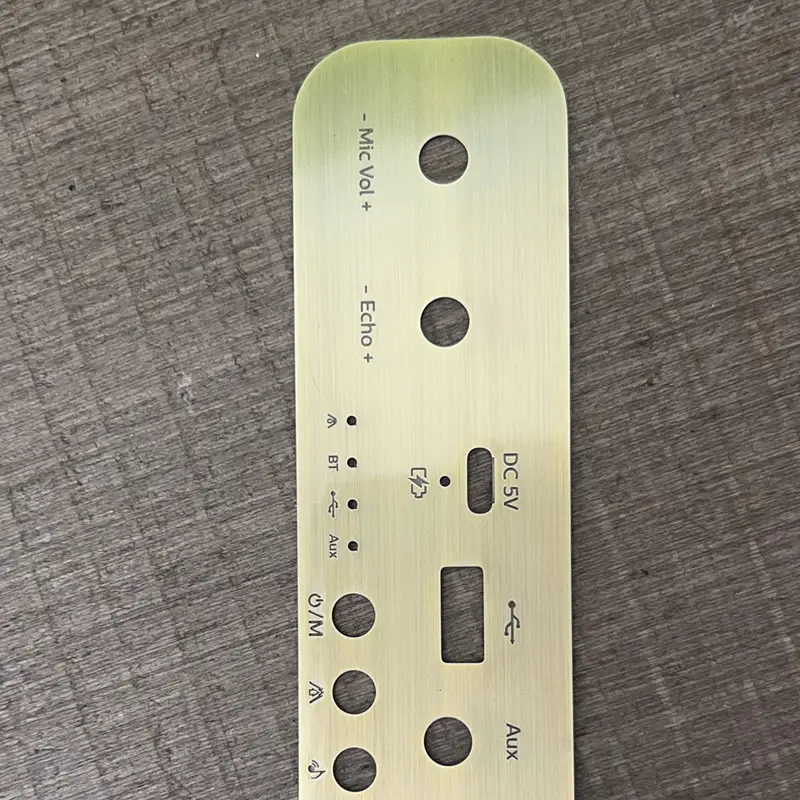

Metal Etching

Metal Etching is a process that uses chemical corrosion or physical bombardment to remove metal surface materials according to the designed pattern to form concave and convex textures, hollow structures or precise patterns. It is widely used in precision parts, decorative parts, electronic components and other fields.

Sheet Metal Materials

Choose from a wide range of sheet metal materials including aluminum, stainless steel, and brass. Each material is chosen for its unique properties, allowing us to recommend the best match for your project’s specific needs and applications.

| Material | Picture | Description |

|---|---|---|

| Cold-rolled steel |  | Cold-rolled steel is processed at room temperature, resulting in a smoother surface and greater strength compared to hot-rolled steel. We support grades such as SPCC, Galvanized Steel (SGCC / SECC), Q235, Steel 1020, and DX51D, often used in precision manufacturing, automotive parts, and home appliances. |

| Aluminum |  | Aluminum is lightweight, corrosion-resistant, and has excellent machinability. It’s easily machinable and excellent for aerospace and automotive parts. We support various grades like 2024,5052,5083, 6063,7075 and 6061 (It can be cut with laser cutter but not bender). |

| Copper |  | Copper stands out for its electrical and thermal conductivity. It’s highly ductile, making it a top choice for electrical components, roofing, and plumbing. We support various grades like Copper C101(T2),C103(T1),C103(TU2),C110(TU0) Note: Sheet metal process can not process more than 5 mm thickness of copper. |

| Brass |  | Brass is an alloy of copper and zinc, offering good corrosion resistance and machinability. We can process popular grades like c360,c385,c377,c464, and c230, often used in fittings, valves, and decorative parts. Note: Sheet metal process can not process more than 5MM thickness of brass. |

| Stainless Steel |  | Stainless steel is renowned for its corrosion resistance. It is strong, easily cleaned, and maintains an attractive finish, making it suitable for medical, food processing, and marine applications. We offer support for grades like 304,316,17-4 PH, 2205, 2507, and 430, suitable for industries such as medical, food processing, and construction. |

Surface Finishing for Sheet Metal Parts

We offer a variety of custom surface finishes to enhance the appearance, performance, and durability of your sheet metal parts. Our surface finish options are designed to meet diverse industry requirements, providing both functional and aesthetic benefits.

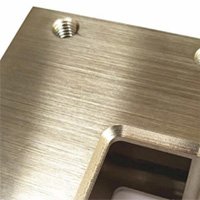

As Machined As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks. | Powder Coating Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces. | Anodizing Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts. | Polishing Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals. |

Sand Blasting Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish. | Brushed Finish A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface. | Electroplating Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity. | Black Oxidize Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection. |

Electropolish Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance. | Alodine Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces. | Electrophoresis Electrophoresis is the motion of dispersed particles relative to a fluid under the influence of a spatially uniform electric field. | Etching Laser etching, also called laser engraving or laser marking, is used to create a visible mark on the surface of many substrates, including metal, plastic, stone and glass. |

Tumbling Utilizes barrel or vibratory processes with abrasives to smooth and polish the surface of parts. | Teflon Coating Applies a protective layer of PTFE to reduce friction and enhance corrosion resistance. | Electroless Plating Deposition of a metal coating on substrates using an autocatalytic chemical process. | Painting Application of paint for aesthetic improvements and protective coatings. |

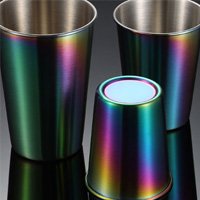

Passivation Chemical treatment to enhance the corrosion resistance of metals by removing free iron from the surface. | PVD Physical vapour deposition (PVD) is a process used to produce a metal vapour that can be deposited on electrically conductive materials as a thin, highly adhered pure metal or alloy coating. | Silkscreen Silkscreen generally refers to screen printing, which is the process of pressing ink through a stencilled mesh screen to create a printed design, graphics and text. |

Advantages of Sheet Metal Fabrication

Sheet metal fabrication is a highly versatile and efficient manufacturing processs from protottypes to high-volume production. It includes techniques like stamping, laser cutting, welding, offering high precision and consistency-even on complex designs. Combined with CNC machining or finishes like powder coating, it’s a go-to for industries ranging from electronics to heavy machinery.

The benefits are clear: it’s cost-effective, especially for large runs, with fast turnaround times. The durable, strong metal parts can also be customized with different materials and finishes to suit specific needs. Whether you’re working on engineering projects or large-scale manufacturing, sheet metal fabrication delivers flexibility, quality, and efficiency.

• High Precision and Consistency: Achieves tight tolerances and complex designs consistently across large production runs.

• Cost-Effectiveness: Particularly efficient for high-volume projects due to streamlined processes like stamping and punching.

• Durability: Metal parts are inherently strong, with options to enhance through various finishing processes.

• Versatility: Suitable for a wide range of applications, from electronics to heavy machinery.

• Customization: Easily tailored to specific requirements, allowing for a broad selection of materials and finishes.

Applications of Sheet Metal Fabrication

Sheet metal fabrication creates a wide range of parts and components, each designed for specific functional and aesthetic needs:

• Enclosures & Casings: Protects machinery and electronics, providing structural integrity and heat resistance.

• Brackets & Mounts: Offers secure support and mounting solutions across applications.

• Panels & Chassis: Forms the framework for vehicles, electronics, and machinery.

• Ductwork & Ventilation: Key for HVAC systems, ensuring efficient airflow and temperature control.

• Custom Shelving & Storage: Custom solutions for organizing and storing items securely in commercial and industrial spaces.

• Decorative Elements: Adds aesthetic value to buildings, vehicles, and consumer products.

• Prototypes: Enables rapid development and testing of new designs and ideas.

Sheet Metal Fabrication FAQs

First, prepare a detailed design of your part or component. If you’re unsure about the specifications, our team of experienced engineers is ready to assist you in optimizing your design for fabrication.

Next, upload or email your design files to us. Here, Once submitted, you will receive a customized quote based on your project’s requirements.

After you approve the quote, we’ll begin the fabrication process. Our advanced machinery and skilled technicians ensure precision and quality. You’ll be updated throughout the process, from manufacturing to the final delivery of your parts.

We accept 3D CAD files in STL, STP, STEP, OBJ IGS, or IGES format and 2D drawings(jpg, png, gif, BMP, pdf) with dimensional details and specific manufacturing requirements.

We respond within 2 hours after your request. Princing quote will be send within 8 hours.

We work with a variety of materials including Aluminium (5052, 6061, 6063, 1060), Carbon Steel (SPCC, HRS, SAPH440), Stainless Steel (201, 304, 316), and Cold Galvanized Steel,etc.

The lead time for receiving your custom sheet metal parts depends on several factors including the complexity of the parts, the quantity ordered, and the specific fabrication processes required. For simple parts, we can often deliver within as little as 3 days from the time your order is placed and the design is confirmed.

For more complex assemblies or larger volumes, the production time will be extended accordingly. Once you submit your design, we provide an estimated delivery timeline along with your quote. This estimate takes into account the current workload in our fabrication facilities and the specific requirements of your project.

We strive to minimize turnaround time without compromising on quality, ensuring you receive your parts as quickly as possible while maintaining the highest standards of fabrication.

Our equipment and techniques can handle a wide range of thicknesses, from 0.006"/0.15mm to 0.25"/6.35mm, depending on the material and the process used.

Chuckmetal supports projects of all sizes. We accommodate both small and large production runs, offering our services for everything from a single prototype to mass production. Importantly, we do not enforce a strict minimum order quantity. This flexibility allows customers, whether startups or large corporations, to leverage our sheet metal fabrication services tailored to their specific needs and scales.

Yes, Chuckmetal is able to handle your shipment for products manufactured by Chuckmetal. With our Freight Forwarding Agency services, you benefit from a seamless integration of logistics and shipping operations,and address any issues that may arise, providing you with peace of mind throughout the shipping process.You Can Choose 6 Shipping Methods at least: air freight, sea freight, rail freight, FCL, LCL,DDP, etc., shipments to various countries.

We respect your intellectual property. None of your information, images, files or likenesses will be shared with any third party, and it will not be used for any advertising, marketing, or promotional use without your explicit written authorization. If you would like to sign NDA agreement, please contact our team for support.

We follow the ISO/IATF standard and guarantee that we will rework the products or refund them if there are any quality problems. The full-dimensional report, material certification, or first article inspection are provided on request before order placement.