Comprehensive Manufacturing Service

Chuckmetal offers a complete suite of precision metal services to support your project from initial concept to final shipping.

Precision quality with 3-day lead time

High precision capabilities

20+ materials, 10+ finish options

ISO manufacturing standards

Prototyping and low-volume manufacturing

Chuckmetal can assist you with all the essential and complex tasks involved in creating and prototyping custom products, from initial design concepts to mass production, logistics, and more. We have a long-standing quality assurance program to ensure that everything—from design to finished products—is of the highest quality. Our team of experts is here to help you turn your designs into high-quality products. Don’t hesitate to tell us about your project!

Upload your design to get started and get an instant quote for custom prototypes and production parts.

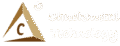

Sheet metal Fabrication/manufacturing

Sheet metal fabrication includes a series of manufacturing processes such as welding, bending, cutting and machining, casting, powder coating, and more

CNC Machining

CNC machining can help simplify the manufacturing process, speed up the production of large batches of machined components, and achieve higher levels of accuracy and precision.

metal Casting

Metal casting is a processing method in which molten metal (such as iron, aluminum, copper, etc.) is poured into a pre-made mold and, after cooling and solidification, a casting with a certain shape, size and performance is obtained.

Tube/Pipe Bending

The pipe processing technology uses external force to make the straight tube/pipe plastically deform and bend it into a pipe fitting with a specific curvature radius and angle. It is widely used in aviation, automobile, construction, bathroom and other fields.

Aluminum profiles

Aluminum profiles refer to linear aluminum products with certain shapes, dimensions and properties made from aluminum ingots or aluminum alloys through specific processing techniques.

Surface Treatment

We offer a wide range of high-quality surface finishing services to enhance your parts’ aesthetics and functions.Choosing the right surface finish for your product and application is crucial for its appearance, performance and lifespan. With our extensive industry experience and NPI expertise, we provide technical feedback to help you make the best choice.

Assembling

We have many dedicated and skilled production line offering assembly services, we can take your instruction us and return the exact metal components you are looking for and can integrate assembly with our fabrication services for a seamless, one-vendor solution.

Packaging

We specialize in packaging solutions:

Design Focus: Tailor packaging with your desired wording and style, fine-tuned by designers until satisfaction. Covers stickers, paper cards, plastic items, color boxes, etc.

Transport Assurance: Professional packing designs and methods ensure safe domestic/international delivery, guaranteeing products arrive intact.

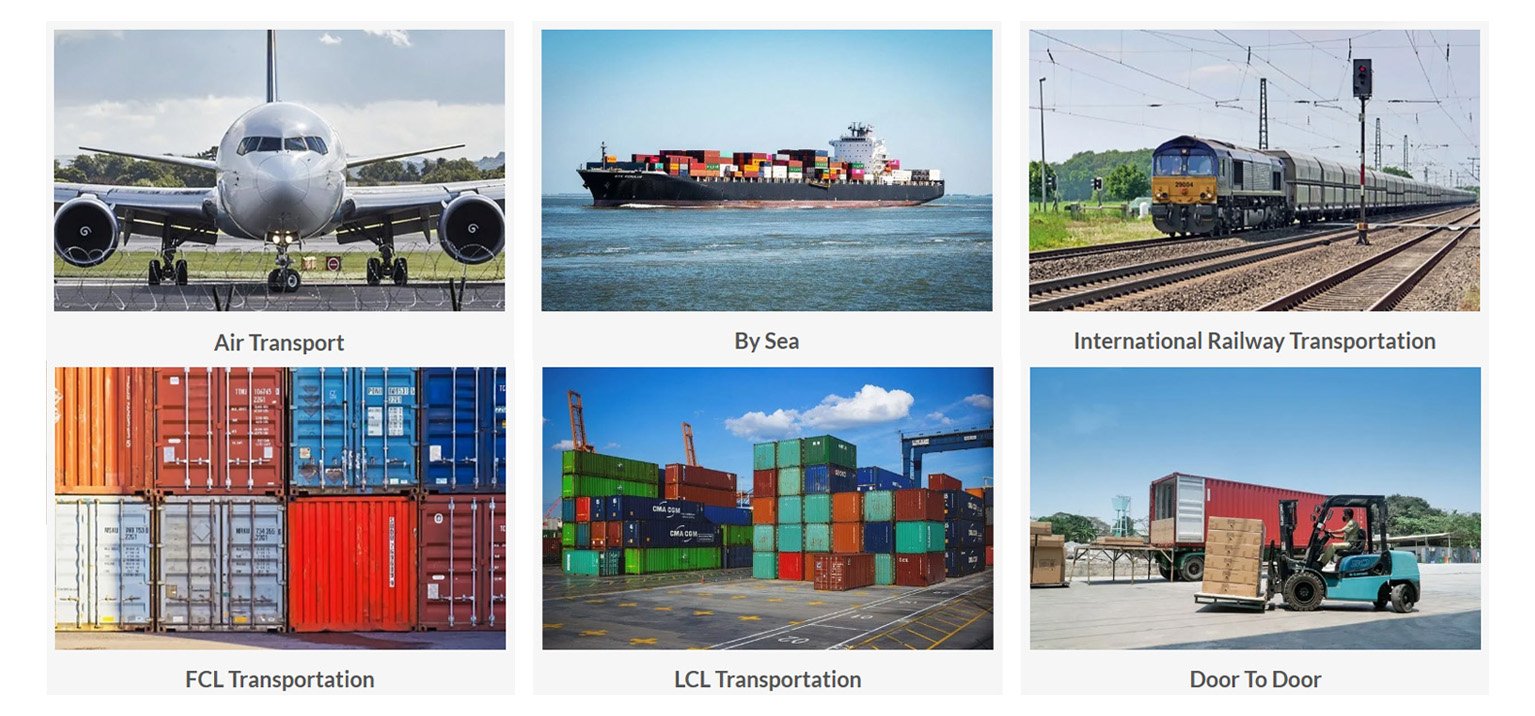

Shipping

With our Freight Forwarding Agency services, you benefit from a seamless integration of logistics and shipping operations. Our International Shipping Agent team works tirelessly to address any issues that may arise, providing you with peace of mind throughout the shipping process.You Can Choose 6 Shipping Methods at least: air freight, sea freight, rail freight, FCL, LCL, DDP,etc.

How it Works

Instant Quote

Send us 2D & 3D design files, then get free DFM feedback and quotes in a few hours.

Production

Once the quote and order are confirmed, production starts in a few hours.

Delivery & Receive

After passing quality inspections, the parts are carefully packed and ready for shipment.

Why Choose Chuckmetal

Chuckmetal combines High-Tech Fabrication & Engineering Partnership—going beyond fabrication to partner with you for design optimization, cost savings, and faster market launch. With in-house project management and strict quality checks, we deliver precision, speed, and full accountability.

♦20+ years of industry experience

♦Fully Automated Production

♦Integrated Project Management

♦Stringent Quality certified: ISO 9001, AS9100D, ISO 13485

More than a manufacturer—we’re your strategic partner to turn ideas into market-ready products faster, smarter, and more efficiently.