CAPABILITIES

Custom CNC Machining Service

Get precise and complex machined parts from ProleanTech. Our Custom CNC Machining Service offers quick prototypes to full-scale production tailored to your needs.

We have the capability of CNC Milling, Turning, Drilling, and many other processes.

- Tolerances down to ±0.0002″ (0.005mm)

- Parts as Fast as one day

- 50+ Material Options

ISO 9001:2015, ISO 13485, IATF 16949:2016 Certified

All technology files are secure and confidential.

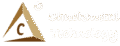

CNC Milling

Our CNC milling services have 3, 4, and 5-axis milling machines. They can cut the workpiece along multiple axes.

CNC Turning

With our latest CNC lathes and turning centers, even the most complex turned parts are possible

Turning-Milling

Allow multiple operations on a single machine, perfect for high precision parts with complex geometries

Electrical Discharge

Highly accurate machining service of cutting metal to precise shapes using electricity

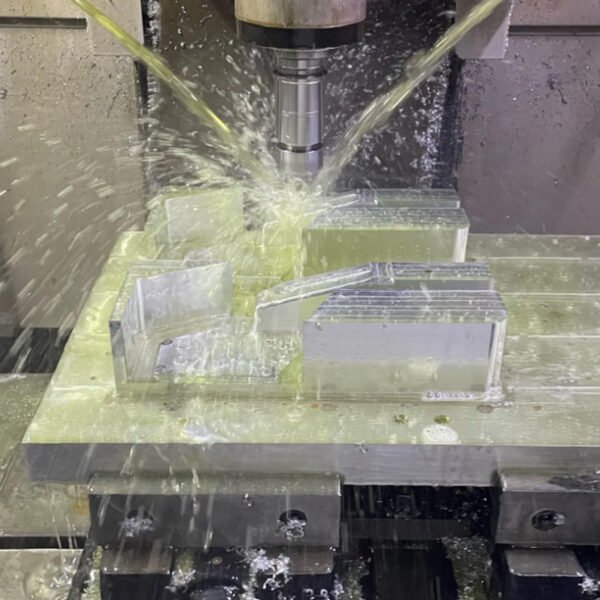

Wire Cut

Our wire cut services can provide high precision tolerances, as tight as ±0.0002″ for an array of industries and applications.

Chuckmetal’s CNC Machining Capabilities

| Parameter | Specification |

|---|---|

| Machining Processes | CNC Milling, Turning, Turn-Milling, and Swiss Turning |

| Part Size | 2000 mm x 1500 mm x 600 mm |

| Minimum Wall Thickness | 0.8 mm (metals), 1.5 mm (plastics) |

| Linear Tolerances | ±0.0002” (0.005 mm) |

| Minimum Feature Size | 0.5 mm or Ø 0.50 mm |

| Minimum Cutting Depth | 0.3 mm |

| Cavity Depth | 4x width (w) |

| As Machined Finish | Ra 125 or better |

| Undercut Width (T-slot) | 3-40 mm |

| Complex Features | Curved surfaces, undercuts, deep cavities, grooves, complex contours, asymmetrical features, etc. |

Why Choose Our CNC Machining Service

Are you looking for precise metal and plastic parts for your project? Here is why you should choose CNC machining services.

Reliable Production

CNC machining’s automatic control and minimal human intervention in operations make it a highly reliable manufacturing method. Additionally, there is significantly lower downtime with CNC.

Volume Flexibility

It is adaptable for all volumes, from small batches to large-scale manufacturing without compromising the quality. So, businesses get scalability options at a low cost.

Automation & Speed

High levels of CNC automation lead to faster production cycles. Meanwhile, automated tool changes and programmed instructions allow rapid production of complex parts.

Complex Features & Profiles

The diverse tooling options and multi-axes capability of CNC machines can craft intricate geometries and profiles like undercuts, threads, pockets, curves, patterned holes, grooves, and irregular profiles.

Cost-effective

Once tooling is set, you can run multiple cycles for identical items. This makes it cost-effective for medium to large volumes, whereas the rapid tooling approach reduces the cost of prototyping and small volumes.

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

1.Get A Quote Immediately

Upload your design CAD file or email our engineer directly and get your quotes as fast as one hour.

2.Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

3.Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

![]() We generally evaluate production and provide quotations within one hour. If you need a more urgent quote immediately, please contact us through our official WhatsApp account.

We generally evaluate production and provide quotations within one hour. If you need a more urgent quote immediately, please contact us through our official WhatsApp account.

CNC Machining Materials Options

The properties of final parts or products depend on the material type. Therefore, CNC machining material selection is critical for any project. Make your choice based on requirements, metals, plastics, or composites.

You have a lot of options for CNC metals such as aluminum, stainless steel, brass, titanium, etc. Consequently, each of these metals has different alloy grades with unique composition and properties. Meanwhile, You can machine CNC plastics like ABS, Acrylic, PEEK, PC, etc.

| Metal CNC Machining | Description |

|---|---|

| Aluminum Alloys | Aluminum is a silver-colored, low-density metal used in a wide range of commercial applications. Under most conditions, unalloyed aluminum is ductile, has moderate strength, and is highly corrosion-resistant. Appropriate alloying elements (Cu, Mg, Mn, Si, etc.) and subsequent heat/work treatments can significantly strengthen aluminum. Because of its low density and corrosion resistance is widely used in aerospace, transportation, architectural, food, and chemical handling (cookware, pressure vessels, etc.) industries. Chuckmetal offers a complete Aluminum CNC machining service and can produce custom Aluminum parts in a variety of shapes and grades, including 1100, 2011, 2024, 3003, 4017, 5052, 6061, 6063, and 7075. |

| Stainless Steel | Stainless steel is a steel alloy that is more corrosion resistant than carbon/alloy steel. Stainless steel is an iron alloy that contains at least 10.5 percent chromium. The presence of chromium results in forming a thin chromium oxide film on the surface of the steel, known as a passivation layer. This layer prevents corrosion on the steel surface; the higher the Chromium concentration in the steel, the more excellent the corrosion resistance. Stainless steel is an ideal material for food handling/processing, medical instruments, hardware, appliances, and structural/architectural products. Chuckmetal offers a complete Stainless Steel CNC machining service and can produce custom Stainless Steel parts in various shapes and grades, including 17-4, 303, 304, 316, 416, 440C, and more. |

| Copper | Copper alloys are one of the most versatile metals, and they have beneficial properties like corrosion resistance, high thermal conductivity, and very high electrical conductivity. Copper alloys are excellent for different industries such as electrical, construction, transport, and consumer goods. The final product made from copper includes architectural parts, coinage, condenser/heat exchangers, plumbing, radiator cores, musical instruments, locks, fasteners, hinges, ammunition components, and electrical connectors. Chuckmetal offers a complete Copper CNC machining service and can produce custom Copper parts in a variety of shapes and grades, including Copper C110 and C101. |

| Brass | Brass is a mixture of copper and zinc. Small amounts of zinc elements are frequently added to improve specific properties. Depending on the part of zinc added to the alloy, the color of brass can range from red to yellow. Alloying can increase strength, hardness, electrical and thermal conductivity, corrosion resistance, and color. Brass is also germicidal, which means it can kill microorganisms when they contact it. Brass is used in various applications and products, including decorative items, architectural parts, condenser/heat exchangers, plumbing, radiator cores, musical instruments, locks, fasteners, hinges, ammunition components, and electrical connectors. Chuckmetal offers a complete Brass CNC machining service and can produce custom Brass parts in various shapes and grades, including Brass C260 and C360. |

| Alloy steel | Alloy steel contains trace amounts of one or more alloying elements (other than carbon), such as manganese, silicon, nickel, titanium, copper, chromium, and aluminum. Alloying provides it with unique qualities not present in standard carbon steel. Due to its low cost, wide availability, ease of processing, and superior mechanical rates, alloy steel is ideal for industrial applications. In general, alloy steels are more malleable to heat and mechanical treatment than carbon steels. Chuckmetal offers a complete Alloy Steel CNC machining service and can produce custom Alloy Steel parts in various shapes and grades, including 4130, 4140, 4340, and more. |

| Mild Steel / Low Carbon Steel | Mild steel is a type of carbon steel with a low amount of carbon. It is also known as “low carbon steel.” Low carbon means it has very little carbon and other alloying elements to block dislocations in its crystal structure, resulting in less tensile strength than high carbon and alloy steels. Mild steel has good weldability and machinability, making it a popular choice for consumer products. Chuckmetal offers a complete Mild Steel CNC machining service and can produce custom Mild Steel parts in a variety of shapes and grades, including Hot and Cold Rolled, Commercial Quality, Galvanized, 1018, 1020, 1026, 1020/1026, CR 1045, HR 1045, 12L14, CR 1215 and more. |

| Tool Steel | Tool steel is a type of carbon alloy steel. It is frequently used to create, modify, or repair hand tools and machine dies. Tool steel is notable for its hardness, abrasion, and deformation resistance. Because steel can retain a cutting edge at extremely high temperatures, it is frequently used to shape other materials via cutting, pressing, coining, or extruding. Because of their abrasion resistance, they are commonly used in the production of injection molds. Tool steel is widely used in dies (stamping or extrusion), cutting, mold production, and impact applications such as hammers (personal or industrial). Chuckmetal offers a complete Tool Steel CNC machining service and can produce custom Tool Steel parts in various shapes and grades, including A2, D2 and O1, and more. |

| Titanium | Titanium alloys are alloys composed of titanium and other chemical elements. Titanium alloys are light in weight, have incredibly high tensile strength and toughness, are extremely corrosion resistant, and withstand extreme temperatures. Titanium alloys are widely used in military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, high-stress components such as connecting rods on high-end sports cars, and some premium sports equipment and consumer electronics. Chuckmetal offers a complete Titanium CNC machining service and can produce custom Titanium parts in various shapes and grades, including Titanium Grade 1, Titanium Grade 2, and Titanium Grade 5. |

| And more | There are many more other metal and alloy materials for different applications. No matter it’s on our material list or not, we could source them for your project. |

| Plastic CNC Machining | Description |

|---|---|

| ABS | ABS is a plastic material with three main ingredients: acrylonitrile, butadiene, and styrene. Each of these monomers imparts specific properties, making ABS terpolymer with robust features. ABS has good strength, toughness, and resistance to impact and temperature. It is easily molded and gives a high-quality glossy surface finish. This plastic polymer does not have a specific melting point. Chuckmetal offers a complete ABS machining service and can produce custom ABS parts in various shapes and grades. |

| PA(Nylon) | Nylon plastic (PA) is a synthetic thermoplastic polymer commonly used in injection molding applications. It’s a versatile, durable, flexible material often used as a more affordable alternative to silk, rubber, and latex. Chuckmetal offers a complete Nylon machining service and can produce custom Nylon parts in a variety of shapes and grades. |

| PC | Polycarbonate(PC) is a thermoplastic polymer containing carbonate groups in their chemical structures. Polycarbonate has good stiffness and thermal resistance due to its molecular structure and reasonably high viscosity. Polycarbonates can be molded and thermoformed with great ease, making them a popular choice for a wide range of products. Chuckmetal offers a complete polycarbonate machining service and can produce custom polycarbonate parts in a variety of shapes and grades. |

| PE | Polyethylene (PE) is generally divided into multiple groups based on density. These include low-density polyethylene (or LDPE), medium density polyethylene (MDPE), high-density polyethylene (HDPE), and ultra-high molecular weight polyethylene (UHMWPE or UHMW). The higher the density, the higher the tensile and flexural strength, chemical and abrasion resistance, and surface hardness. Chuckmetal offers a complete Polyethylene machining service and can produce custom Polyethylene parts in a variety of shapes and grades. |

| PET | PET(Polyethylene Terephthalate) or polyester is a semi-crystalline resin with a good balance of strength, stiffness, toughness, a natural high gloss finish, excellent chemical resistance, and good dielectric properties. PET is approved as safe for contact with foods and beverages worldwide; PET is sustainable, completely recyclable, and they are the most recycled plastic. PET is commonly used in Plastic components in electrical products, Electrical encapsulation or insulation, Electrical insulation polymers, Connectors for electrical, Packaging or containers for consumables and food, and Appliances. Chuckmetal offers a complete PET injection molding service and can produce custom PET parts in various shapes and grades. |

| PMMA(Acrylic) | Acrylic(PMMA) is a glass-like plastic, their excellent weatherability, good resistance to fading caused by UV and fluorescent lighting, and high resistance to scratching, durability, and natural transparency mak it a good material choice for food storage containers, refrigerator drawers,automotive and consumer products. Acrylics are also well-suited to overmolding and other specialized injection molding processes. Chuckmetal offers a complete Acrylic injection molding service and can produce custom Acrylic parts in various shapes and grades. |

| POM (Acetal) | Polyoxymethylene (POM), also known as Delrin® or Acetal, is a thermoplastic engineered material used to make parts that require increased stiffness, low friction versatility, and more excellent dimensional stability. POM has high tensile strength, wear resistance, creep and warp resistance, and overall toughness and durability. POM is widely used in manufacturing gears, bearings, conveyor parts, automotive parts, sporting equipment, electrical components, sliding and guiding parts, and so on. Chuckmetal offer a complete POM/Delrin®/Acetal injection molding service and can produce custom POM parts in various shapes and grades. LEADRP will work with you to produce injection molded Delrin® parts that meet the exact specifications of your project. |

| PTFE | Polytetrafluoroethylene (PTFE), also known as Teflon®, is a synthetic tetrafluoroethylene with numerous applications. PTFE has high thermal stability, good chemical resistance, and high-temperature resistance. PTFE products also have excellent sliding properties, electrical resistance, and a nonstick surface. PTFE can be reinforced with glass fiber, carbon, or bronze additives to improve mechanical properties. Due to its structure, PTFE is frequently formed into semi-finished products using compression molding and then machined with cutting/machining tools. |

| PC | Polycarbonate is also a transparent plastic but is more durable and shatterproof than acrylic. It is also UV-stabilized and flame-retardant. While machining, the PC is prone to stress cracking and requires slow feed rates and sharp tools. Polycarbonate machining is widespread in food and beverage, packaging, medical devices, eyewear, electronics, etc. |

| PEEK | PEEK is a family of high-performance thermoplastics. The name PEEK is derived from the words polyether ether ketone. PEEK is a engineering plastic used for a wide range of applications where it needs to be strong and tough. It has good chemical resistance and can withstand high temperatures up to 260°C. PEEK has excellent mechanical properties, making it suitable for applications such as medical implants, automotive components, and even aeronautical parts. PEEK is also used in electronic components such as connectors and insulators. |

| PP | Polypropylene (PP) is a polyolefin or saturated polymer, like polyethylene (PE) and polybutene (PB). PP is one of the most versatile polymers with good chemical resistance, fatigue resistance, better temperature resistance, and lower density than HDPE. PP is widely made for buckets, bowls, crates, toys, medical components, washing machine drums, battery cases, and bottle caps. PP can be elastomer modified for bumpers and talc-filled for added stiffness at high temperatures. Chuckmetal has been producing injection-molded polypropylene parts for over 10 years. Our team has extensive experience and expertise in delivering molded PP parts in even the most complex shapes. We can help you decide which of these plastic materials is best suited to your specific application. |

| And More | For Example: High Performance Plastics, Engineering Plastics, Industrial Plastics, Biocompatible Materials, Food Safe Plastics, and Other Modified Thermoplastics. |

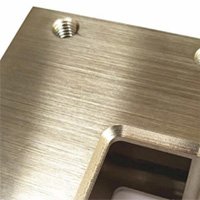

Surface Finishing Options

Surface finish is applied to parts after they have been machined to create a unique surface layer to meet the hardness, chemical resistance, and appearance requirements of the products. It depends on material properties and the application of the part. Chuckmetal provides almost all types of surface finish processes.

Anodizing Anodizing can improve the corrosion resistance of aluminum alloys, increase the surface hardness and wear resistance of aluminum alloys, and have a good appearance after coloring treatment. Type II traditional anodizing and Type III hard coat anodizing service is available. | Powder Coating Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces. | Anodizing Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts. | Polishing Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals. |

Sand Blasting Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish. | Brushed Finish A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface. | Electroplating Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity. | Black Oxidize Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection. |

Electropolish Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance. | Alodine Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces. | Electrophoresis Electrophoresis is the motion of dispersed particles relative to a fluid under the influence of a spatially uniform electric field. | Etching Laser etching, also called laser engraving or laser marking, is used to create a visible mark on the surface of many substrates, including metal, plastic, stone and glass. |

Tumbling Utilizes barrel or vibratory processes with abrasives to smooth and polish the surface of parts. | Teflon Coating Applies a protective layer of PTFE to reduce friction and enhance corrosion resistance. | Electroless Plating Deposition of a metal coating on substrates using an autocatalytic chemical process. | Painting Application of paint for aesthetic improvements and protective coatings. |

Passivation Chemical treatment to enhance the corrosion resistance of metals by removing free iron from the surface. | PVD Physical vapour deposition (PVD) is a process used to produce a metal vapour that can be deposited on electrically conductive materials as a thin, highly adhered pure metal or alloy coating. | Silkscreen Silkscreen generally refers to screen printing, which is the process of pressing ink through a stencilled mesh screen to create a printed design, graphics and text. |